ASTM standards are carefully developed specifications and test methods designed to evaluate materials, products, systems, and services. Each standard defines a consistent, repeatable way to measure performance characteristics such as strength, durability, colorfastness, flammability, and more.

These standards are developed through a consensus process involving industry experts, manufacturers, testing laboratories, and government agencies, ensuring that each method reflects real-world needs and scientific integrity.

Why ASTM Standards Matter

ASTM standards play a crucial role across virtually every industry. Here’s why they’re essential:

-

✅ Quality Assurance: ASTM standards provide a measurable way to confirm that products meet defined performance requirements.

-

✅ Safety Compliance: Many ASTM standards are referenced in national and international building codes, ensuring public health and safety.

-

✅ Market Confidence: Products tested according to ASTM standards carry credibility with regulators, specifiers, and consumers.

-

✅ Global Recognition: ASTM standards are accepted worldwide, facilitating international trade and compliance.

-

✅ Innovation Support: Clear testing methods help manufacturers compare materials and refine products with reliable data.

Examples of Common ASTM Standards in Product Testing

ASTM standards cover a wide range of industries and materials. Here are a few examples commonly used in laboratory testing:

-

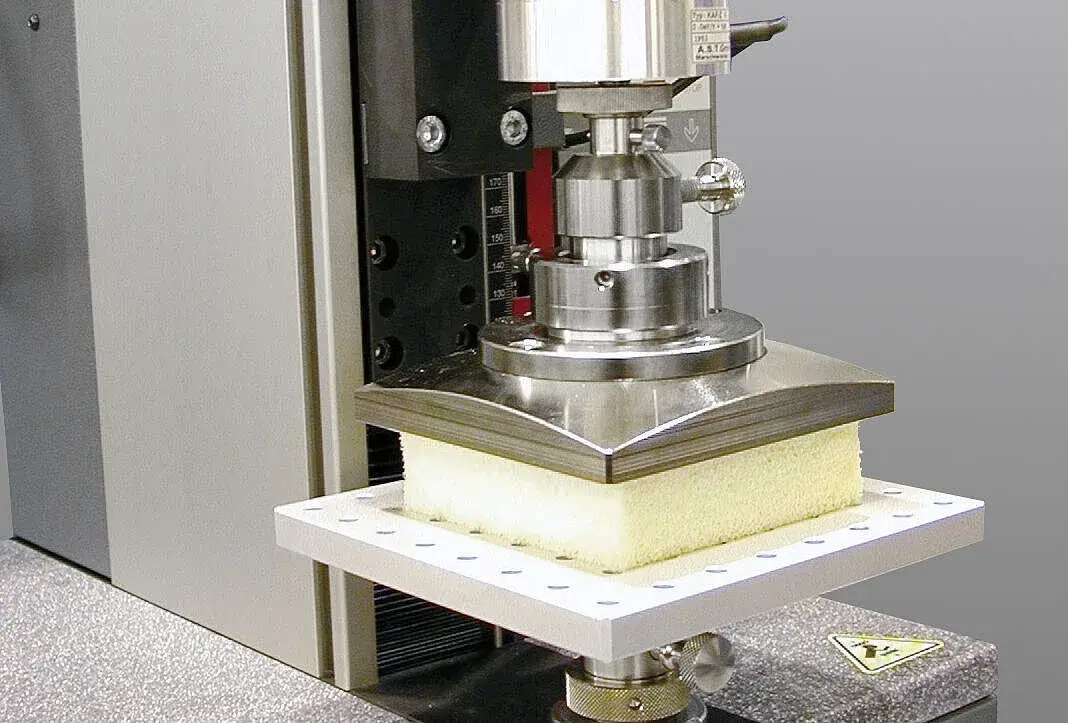

ASTM D3574 – Evaluates the properties of flexible cellular materials like polyurethane foam.

-

ASTM D6540 – Measures the soiling resistance of carpet finishes through accelerated wear testing.

-

ASTM E119 – Tests the fire resistance of building materials and assemblies.

-

ASTM D2047 – Determines the static coefficient of friction for floor surfaces to assess slip resistance.

-

ASTM D5034 – Measures the breaking strength and elongation of textile fabrics.

Each of these standards provides a framework for consistent, reliable testing that manufacturers can depend on for product validation and quality assurance.

How ASTM Standards Support Manufacturers

For manufacturers, adherence to ASTM standards is about more than compliance—it’s about credibility and performance. By testing products according to recognized ASTM methods, manufacturers can:

-

Demonstrate compliance with industry and safety regulations

-

Improve consistency and reduce production defects

-

Validate product claims and performance data

-

Gain a competitive edge with independently verified results

Partnering with a Laboratory That Follows ASTM Standards

Working with an accredited laboratory that performs testing to ASTM standards ensures your results are accurate, reproducible, and recognized throughout the industry.

At Professional Testing Laboratory, we specialize in a wide range of ASTM testing methods, providing manufacturers with dependable data to support product development, certification, and quality control.

Contact us today to learn more about our ASTM testing services or request a quote for your next project.

FAQs About ASTM Standards

1. What does ASTM stand for?

ASTM stands for the American Society for Testing and Materials, now known as ASTM International.

2. What are ASTM standards used for?

ASTM standards define testing and performance criteria for materials and products to ensure consistency, safety, and reliability.

3. Are ASTM standards legally required?

Not all ASTM standards are legally mandated, but many are referenced in building codes, safety regulations, and procurement requirements.

4. How are ASTM standards developed?

They are created through a voluntary, consensus-based process that includes input from industry professionals, scientists, and government agencies.

5. Why should manufacturers follow ASTM standards?

Using ASTM standards ensures product quality, boosts customer confidence, and helps companies meet both national and international compliance requirements.

6. Can ASTM standards change over time?

Yes. ASTM regularly updates its standards to reflect new technologies, materials, and industry best practices.